Table of Contents

I. Introduction

II. What Is Sound Proof Insulation for Walls?

III. Understanding STC Rating

IV. Factors Affecting Soundproofing Performance

V. Selecting Soundproof Insulation for Walls

VI. Installation Tips for Soundproof Insulation

VII: Additional Soundproofing Techniques

VIII. Conclusion

I. Introduction

Noise pollution has become an increasing problem in today’s busy world, particularly urban areas or spaces that value privacy and tranquillity. Soundproofing your walls is a simple yet effective solution to create an uplifting, tranquil, and soothing environment – whether you own a home, manage a business, rent an apartment, or live as a tenant. One such effective method for controlling sound levels through insulation.

Sound proof wall insulation is designed to prevent sound from traveling from one space to the next. By installing soundproof insulation for interior walls, you can create a barrier that absorbs and dampens sound waves – thus decreasing noise entering or leaving rooms.

II. What Is Sound Proof Insulation for Walls?

Sound proof insulation wall (also referred to as sound proof insulation material) is a special material designed to increase soundproofing capabilities of walls. Usually made out of dense and resilient materials that effectively absorb and block sound waves before they pass through walls structures, wall sound proof insulation helps increase wall protection significantly.

Wall soundproofing insulation’s primary purpose is to mitigate noise transmission, whether that be airborne noise (such as voices, music or traffic noise) or impact noise such as footsteps or machinery vibrations. By installing soundproofing into walls you can create a quieter and more relaxing living or working space.

How Does Sound Proof Insulation Work?

Wall insulation soundproof works on the principle of sound absorption and sound blocking. As sound waves pass over an insulation material, they absorb it and convert to heat energy for conversion back into sound energy, helping reduce sound energy that would otherwise pass through walls.

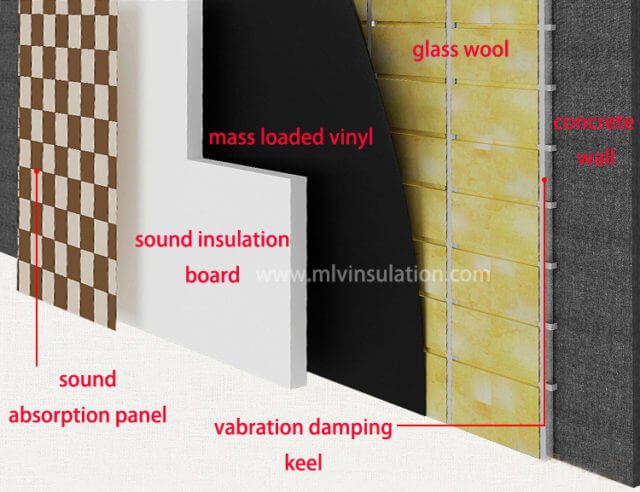

Soundproof insulation materials are designed to prevent sound waves from traveling through walls. Their density and thickness serve as barriers, preventing sound waves from easily passing through. With both its absorption and blocking properties, soundproof insulation proves highly effective at limiting noise transmission.

III. Understanding STC Rating

The STC rating (Sound Transmission Class) is a standard measurement used to evaluate soundproofing performance of materials such as sound proof insulation walls. It provides a numerical value which demonstrates how effectively an insulation and soundproofing material reduces sound transmission through partitions such as walls.

STC ratings play an integral part in evaluating soundproof insulation material. Consumers can compare various materials and make informed decisions based on their individual soundproofing needs; those wishing to purchase higher STC-rated materials typically experience superior soundproofing performance as these can block more frequencies without transmitting noise transmission as efficiently.

Understanding How STC Rating Is Calculated and Measured

STC ratings are determined through a series of sound transmission tests conducted in a controlled laboratory environment. In these tests, sound insulation performance of material samples is tested against various frequencies and intensities of sound waves.

Data obtained during testing is then used to create a sound transmission curve, which shows how different frequencies affect attenuation rates of materials. From this curve can be calculated the STC rating by calculating average sound reduction across a variety of frequencies.

Common STC Ratings of Soundproof Insulation Materials

Different soundproof insulation materials feature different STC ratings to demonstrate their unique soundproofing abilities. Here are some commonly-used soundproof insulation materials and their associated STC ratings:

- Sound Proof Fiberglass Insulation: STC rating ranges from 20 to 35, depending on the thickness and density of the material.

- Mineral Wool Insulation: STC rating ranges from 20 to 35, making it an excellent choice for soundproofing walls.

- Cellulose Insulation: STC rating ranges from 20 to 30, providing effective noise reduction.

- Foam Insulation: STC rating ranges from 15 to 25, with some specialized foam products offering higher ratings.

Note that STC ratings do not fully determine soundproofing performance of materials; other factors, including installation methods and overall wall construction can have an effect.

IV. Factors Affecting Soundproofing Performance

To achieve optimal soundproofing results, various factors beyond material selection must also be considered:

Material Thickness and Density

Thick and dense wall insulation sound proof materials tend to provide superior soundproofing capabilities due to their higher mass and absorption capabilities.

Air Gaps and Sealing Techniques

Proper installation techniques, including tight fitting and sealing any gaps or cracks, are critical to optimizing soundproofing performance. Air gaps allow sound to bypass insulation, lessening its effectiveness; using sealants like acoustic caulk or weatherstripping can help narrow those gaps and enhance soundproofing performance.

Additional Soundproofing Measures

Additional soundproofing measures can sometimes further boost soundproof insulation’s effectiveness. Techniques like double walls, resilient channels or mass-loaded vinyl barriers provide extra layers of soundproofing and reduce sound transmission.

Impact of Construction and Wall Composition on Impact Assessment

Construction and composition of walls can have a major influence on soundproofing performance. Solid materials like concrete or brick provide superior sound insulation compared to lightweight ones like drywall. Understanding the construction and making appropriate changes may lead to improved results in terms of soundproofing performance.

V. Selecting Soundproof Insulation for Walls

When selecting insulation soundproofing walls, several factors should be taken into consideration:

A. Variety of Soundproof Insulation Materials Available

There are various insulation soundproof walls on the market, each boasting unique properties and advantages. Some commonly utilized options are:

- Fiberglass Insulation: Fiberglass insulation is cost-effective insulation for soundproofing interior walls, easily available, and boasts superior sound absorption properties.

- Mineral Wool Insulation: Mineral wool has long been prized for its soundproofing abilities, fire resistance properties, thermal insulation qualities and thermal performance characteristics.

- Cellulose Insulation: Constructed of recycled paper, cellulose insulation offers eco-friendly soundproofing and thermal protection.

- Foam Insulation: Foam insulation such as polyurethane or polystyrene foam insulation is lightweight and straightforward to install, offering decent soundproofing properties but may not be as efficient.

B. Factors to Keep in Mind when Selecting Insulation Solutions

Before selecting insulation for soundproofing walls, keep these factors in mind:

- Assess Your Needs for Soundproofing: Evaluate what noise issues are being created, as different materials offer differing degrees of soundproofing capabilities; select one that aligns with your requirements.

- Space Limitations: Take into account any space limitations within the walls for insulation installation. Some materials require thicker layers for effective soundproofing, which may not always be possible or desirable in all circumstances.

- Fire Safety: For added peace of mind, select materials with fire-retardant properties like mineral wool or certain foam insulation materials.

- Environmental Impact: If sustainability is important to you, opt for insulation materials made of eco-friendly recycled or sustainable materials.

C. Budget Considerations and Solutions

Cost can often be the determining factor when it comes to selecting insulating walls for soundproofing, with more expensive materials often providing superior soundproofing performance. Achieving balance between budget and desired level of soundproofing should always be your goal. Explore various brands and suppliers to identify cost-effective alternatives without compromising on quality, and look out for any discounts or promotions which could lower overall costs.

VI. Installation Tips for Soundproof Insulation

Proper installation of soundproofing interior walls with insulation is critical to achieving optimal results from soundproofing efforts. Here are some essential pointers:

A. Preparing Walls Before Installation

- Keep Walls Clean and Dry: For optimal insulation adhesion, be sure that walls are free from debris or moisture – this will allow it to adhere correctly and help avoid potential issues in the future.

- Seal Cracks and Gaps: Prior to installing insulation, sealing any cracks, gaps, or holes in walls is vital in order to minimize sound leakage and maximize soundproofing performance. Doing this can significantly decrease sound leakage while improving overall soundproofing capabilities.

B. Step-by-Step Guide for Installing Interior Wall Insulation Soundproofing

- Measure and Cut: Take measurements of the wall dimensions before cutting insulation material according to them, leaving a small gap around its edges for expansion purposes.

- Install Insulation: Carefully insert insulation material into wall cavities, taking care to fit it snugly without compressing too much and potentially diminishing soundproofing effectiveness. Avoid compressing too much, which could compromise its soundproofing ability.

- Seal Edges and Joints: Create an airtight seal by applying acoustic caulk or tape around any edges or joints with soundproof caulk to prevent sound leakage and ensure consistent installation across each wall you want to soundproof….

- Repeat for Each Wall: To ensure consistent installation throughout, repeat this process on each wall wishing to soundproof as part of insulating interior walls soundproofing the room.

C. Mistakes to Avoid during Installation of Interior Wall Insulation Sound Proofing

- Leaving Gaps: It is essential that no gaps or spaces exist between the insulation material and walls, even small gaps can compromise soundproofing performance and lead to subpar soundproofing performance.

- Inappropriate Sealing: Be wary of insufficiently sealing edges and joints as this can allow sound leakage, decreasing insulation effectiveness.

- Disregard for Safety Precautions: When handling insulation materials, adhere to all safety guidelines and wear appropriate protective gear such as gloves and masks for your own protection.

By following these installation tips and avoiding common mistakes, you can maximize the soundproofing effectiveness of your walls and create a more peaceful atmosphere.

Soundproofing A Wall | How To Soundproof Walls

The MLV insulation for walls increases mass with minimal thickness. Mass loaded vinyl is usually embedded behind the finished wall, floor or ceiling material.

Soundproof Mats for Walls | Soundproof Materials

Soundproof Materials for Walls Thin Sound Proof Material |Sound Blocking Material for Walls Sound Proofing Mats Soundproof Material for Walls

VII: Additional Soundproofing Techniques

There is no best soundproofing insulation material. Cheap soundproofing insulation is only one component of soundproofing walls effectively; to achieve optimal results it may be beneficial to combine soundproof pipe insulation with other soundproofing methods. Here are a few additional techniques that could enhance your walls’ soundproofing capacities:

A. Combining various soundproofing strategies together could provide an effective method of noise suppression

- Double Stud Walls: To construct double stud walls, construct two parallel walls with an opening between them to act as additional barriers against sound transmission and thus decrease sound transference. This technique helps minimize transmission by acting as an extra buffer to dampen sound waves.

- Resilient Channels: These metal strips, attached to the studs before installing drywall, help decouple walls from structures by dampening sound vibrations that might transmit through walls into structures.

- Mass-Loaded Vinyl (MLV) barriers: Mass loaded Vinyl (MLV) barriers can be used as cheap soundproof insulation to further increase soundproofing capabilities. These heavy, flexible sheets block sound transmission effectively.

B. To achieve optimal results for interior wall soundproofing insulation, consider installing soundproof curtains, acoustic panels or rugs in order to amplify sound absorption

- Soundproof curtains: These curtains are specially designed to absorb and block noise. Constructed with dense materials for maximum noise reduction.

- Acoustic panels: Acoustic panels are designed to absorb sound waves and reduce echo in a room, offering greater soundproofing capabilities by strategically placing them against walls.

- Rugs and carpets: When placed strategically within a room, adding rugs or carpets can help dampen sound transmission by acting as additional barriers against sound transmission, particularly in spaces featuring hard flooring surfaces such as hardwood flooring.

Sound Proofing Boards for Walls | Soundproofing Wall Board

Soundproofing Insulation for Walls Soundproofing Wall Board |Sound Insulation for Interior Walls Soundproof Wall Boards Soundproofing Boards for Walls

Mass Loaded Vinyl for Walls | Mass Load Vinyl Sheet

Mass Loaded Vinyl Existing Wall |Mass Loaded Vinyl on Wall Mass Loaded Vinyl Over Drywall Size 1x5m 1x10m Roll

VIII. Conclusion

How to insulate walls for soundproofing? Soundproof insulation for walls is key for creating an serene environment, as soundproofing wall insulation plays a pivotal role in limiting noise transmission; however, additional techniques should also be considered in order to achieve maximum soundproofing results.

Combine soundproof material for floors and wall insulation soundproofing with double stud walls, resilient channels and MLV barriers to significantly increase their soundproofing capacities. Furthermore, adding soundproof curtains, acoustic panels or rugs may further help in noise reduction efforts.

Soundproof insulation options and techniques should be explored and implemented to create a more peaceful and serene living or working space. A properly soundproofed environment can significantly increase comfort and overall well-being.