Pipe Wrap | Insulation Wrap For Pipes

Pipe Wrap

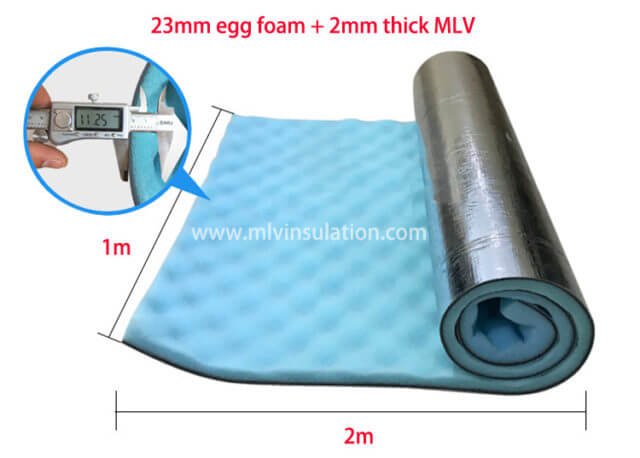

Mass loaded vinyl is a limp barrier material that often be used as pipe wrap insulation material. The high relative density is what makes the mass loaded vinyl so effectively to stop the sound.

What is the difference between mass loaded vinyl and sound batts? Both of them can be used as insulated pipe wrap material. We first need to understand what is a good absorber or barrier. In general, there are only two features, acoustic wool and mass material, that make an effective sound absorber or barrier. Most, if not all, absorbers and barriers have one or both of these features in their designs. The use of these materials in the design of the absorber or barrier, or the way and location of the absorber / barrier in the environment is inspired by acoustic design.

Absorbing sound to a large extent depends on the knowledge and manipulation of sound wavelengths. The fuzzy material absorber works by blurring the porosity of the material (the percentage of pores or gaps, to the total volume of mass). These gaps capture relatively short medium and high frequency acoustic waves and convert the sound energy into heat by friction. To blocking sound is different. The pipe wrap material needs to be dense.

So why is the mass loaded vinyl an effective material for pipe wrap?

Because the MLV has a very small thickness, it is flexible and it is high density! Most high mass materials can not be wrapped or molded into the shape of something, but MLV can wrap around pipe insulation or wrap insulation. The unique combination of small size, quality and flexibility makes mass loaded vinyl a unique material for the world’s sound blocking.

For example, if you need to sound insulate a horizontal pipe in the basement of the family, the typical method used in the past is to place some more acoustic wool in the joist cavity of the pipe. And then put up the ordinary gypsum board ceiling. This is a pipe insulation solution but it takes up lots of space. The floor-to-ceiling height of many basements is not always viable. Sound insulation and soundproof ceilings in these restricted environments are usually easier than mass loaded vinyl.

If we can double the total mass of a given construction project, use only a few millimeters of extra space? This is where mass loaded vinyl is irreplaceable as a rubber pipe wrap material or insulation wrap for pipes.

Back to the previous example of wrap pipe insulation of gray water pipes. Before closing the ceiling, if we wrap the gray water pipe with only 3mm mass load of vinyl, we can effectively double the mass of each foot around the pipe and below the ceiling. Try wrapping pipes in concrete or cardboard or MDF is basically not practical. Think of the labor time you need?

Installation of mass loaded vinyl under the walls, ceilings and floors is a space-saving method, which is very effective for the mass of each cross-sectional dimension.